Megasonic cleaners utilize transducers to emit high-energy sound waves at the megahertz level. Micron and submicron-sized impurity particles on the surface of devices are dislodged after being subjected to the megahertz-frequency oscillation of the liquid, thereby achieving ultra-precision cleaning. Unlike some other cleaning methods, megasonic cleaning does not generate a strong cavitation effect, which prevents surface damage to the cleaned objects and residual contaminants during the cleaning process.

Specific Application Scenarios:

1. Removal of fine particles from wafers, liquid crystals, etc. The cleaning precision can reach 300nm, and the maximum size of substrates that can be cleaned is 400mm × 400mm.

2. Cleaning and drying of optical components; for example, it is suitable for cleaning optical glass used in lenses, prisms, microscopes, etc.

3. Cleaning of optical glass (for touch screens), ITO glass, and other materials: this includes cleaning before coating, before and after tempering, and before polishing.

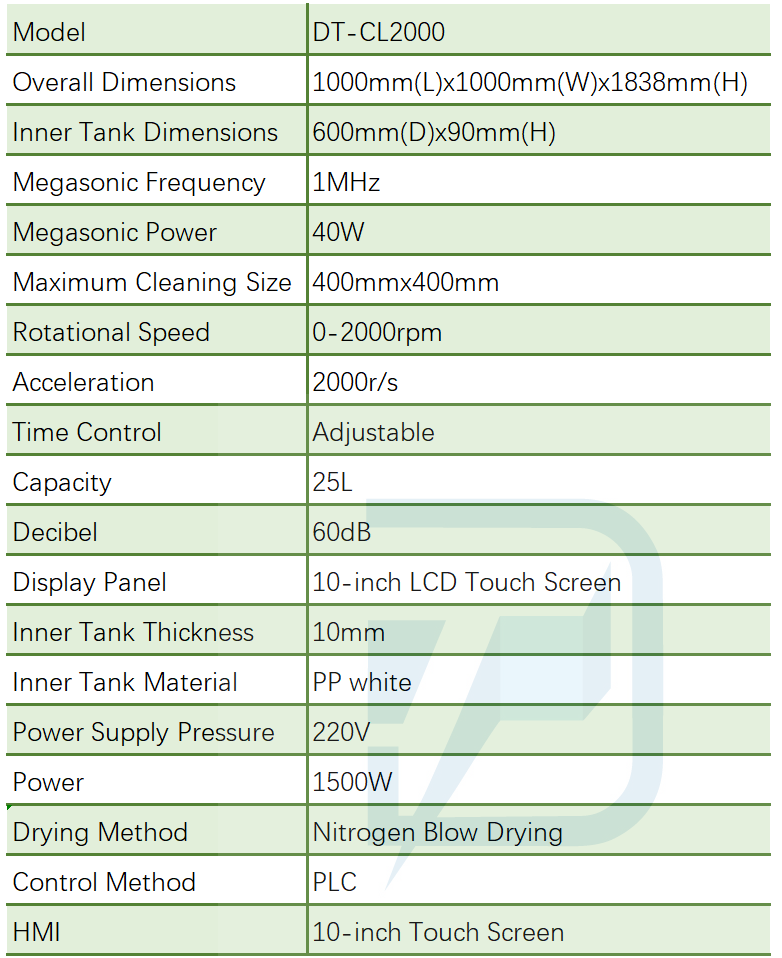

Product main technical parameters:

Contact: Mike

Phone: +86-19820819249

Tel: +86-19820819249

Email: nanofab@diaotuotech.com

Add:

We chat