The workstation comprises a wafer loading/unloading unit, a megasonic cleaning unit, a spin-coating unit, hot/cold plates, and a nanoimprint lithography (NIL) unit. It utilizes a robotic arm to achieve automatic transfer of wafers between different units.

The equipment integrates the pre-processes and post-processes of nanoimprint lithography, enabling a complete processing flow from raw wafers to finished products. Additionally, its functional modules can be added, removed, or adjusted according to user requirements.

Main Functions:

Imprinting Mode: UV nanoimprint lithography (NIL) with heating support;

The equipment uses a flexible film as the template substrate. The template is stretched flat by a tension mechanism, and the tension is adjustable;

The exposure light source is a 365nm UV LED light source, featuring high light intensity and uniform light intensity distribution;

High imprinting uniformity and high aspect ratio;

The equipment is equipped with 4 sets of high-efficiency FFU (Fan Filter Unit) filters, and the internal cleanliness reaches Class 100 or above;

The equipment is configured with control software. It can store no less than 50 sets of process parameters; it can realize automatic cleaning, spin-coating, imprinting, exposure and demolding, and all process parameters are adjustable.

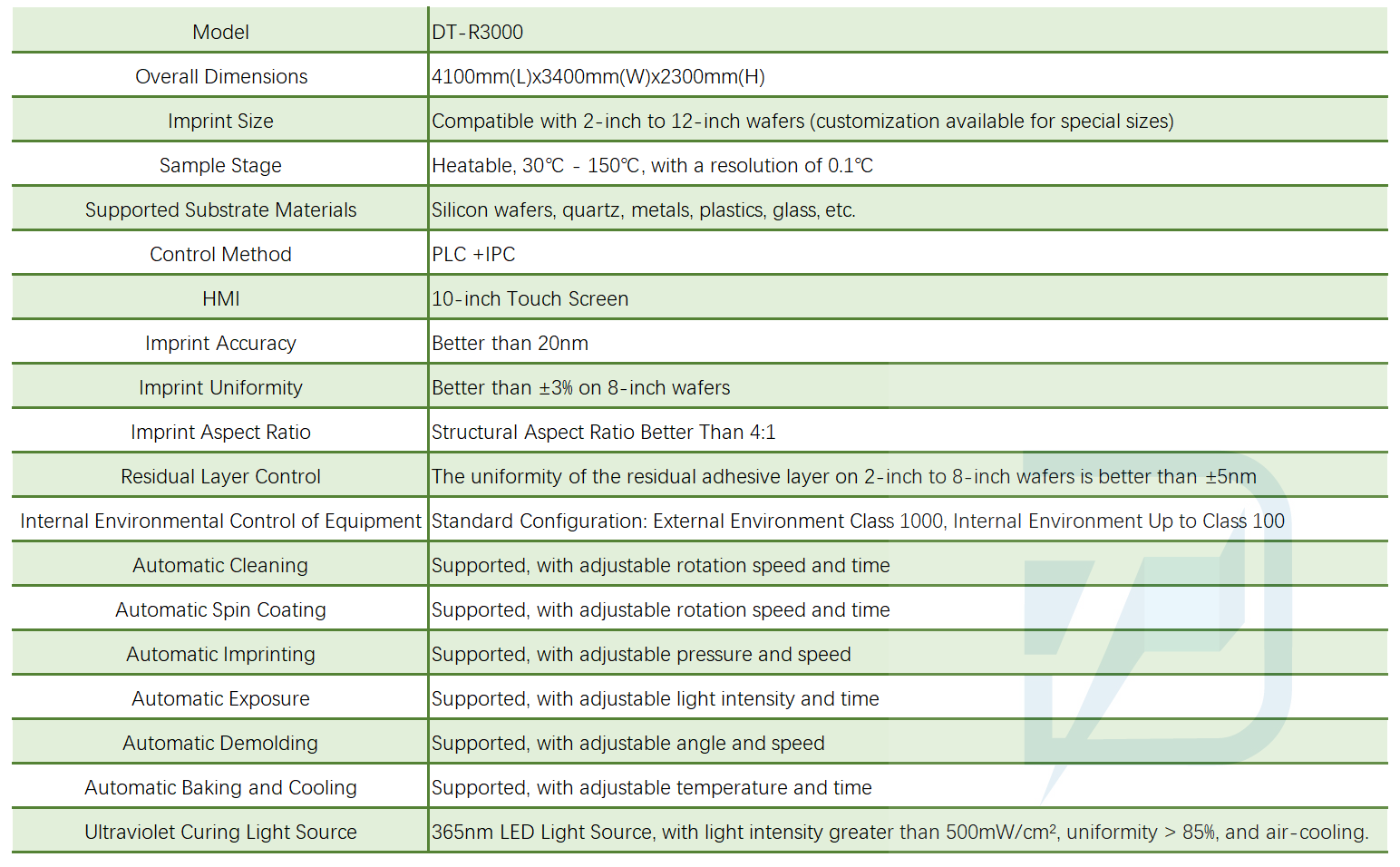

Main Parameters:

Contact: Mike

Phone: +86-19820819249

Tel: +86-19820819249

Email: nanofab@diaotuotech.com

Add:

We chat